Automatic Square Can Production Line

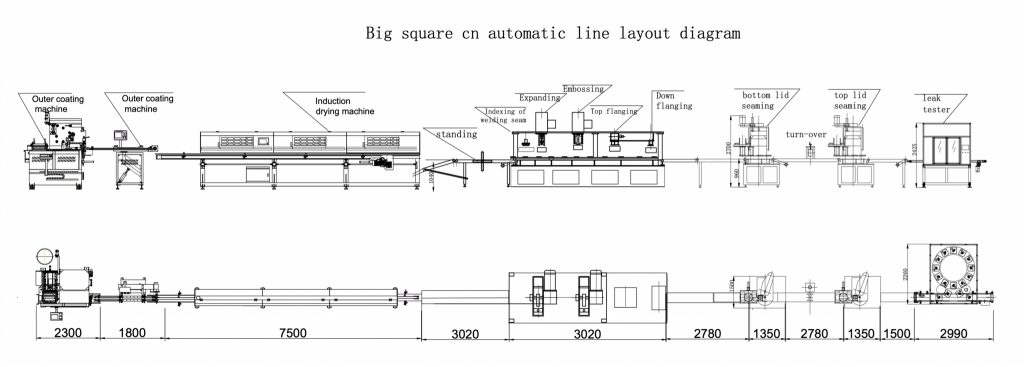

The production line is suitable for the automatic production of 18 liters’square can. total power: approx.90KW,total floor space: 250㎡ .total length:approx.33 meters. total manpower: 4-5 people. Production capacity: 20-23cpm. Square can’s height range: 170-450mm. Square can’s diameter range:300-320mm

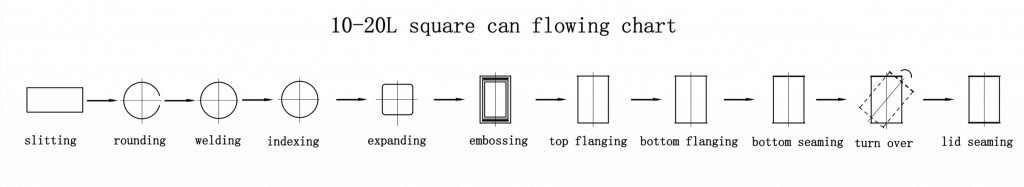

Technical flow: cutting the tin sheet to blank—rounding—welding—inner and outer coating (inner powder coating and outer coating)-drying-cooling conveying-square expanding-panel,corner embossing-upper flanging-lower flanging-bottom lid feeding-seaming-turning over-top lid feeding-seaming-leak testing-packaging

What’s the square can?

It is made of three pieces of metal sheet (mostly tinplate), the can body, the bottom and the lid. The can is square shaped. The body of the can has embossing on all sides, and on four corners. The big square can range: capacity 15-20L, diagonal 300-320mm, height 220-400mm.

Big square can fully automatic production line operating process

First place the cut can body materials into the automatic resistance welding machine’s feeding table, Suck by the vacuum suckers,send the tin blanks to the feeding roller one by one.through the feeding roller, the single tin blank is fed to the rounding roller to conduct rounding process, then it will be fed to the rounding forming mechanism to make rounding.The body is fed into the resistance welding machine and make welding after the accurate positioning. After welding, the can body is automatically fed into the rotary magnetic conveyor of the coating machine for outer coating, inner coating or inner powder coating, Which depends on customer’s various need.It is mainly used to prevent the side welding seam line from being exposed in air and rusting.The can body should be placed in induction drying oven to dry if it’s inner coating or inner powder coating.Afer drying, It will be fed to cooling device to make natural cooling.The cooled can body is then fed to the big square can combination machine, and the can body is in an upright state going through the uprighting conveyor. It is fed to the first automatic side welding seam indexing station by the clamps.The second station is square expanding.When the can body is in position, on the can body lifting tray which is controlled by a servo motor, and the can body is sent by this lifting tray to the square expanding mold to make square expanding.The third station is to make panel and corner embossing. When the can body is in position, on the can body lifting tray which is controlled by a servo motor, and the can body is sent by this lifting tray to the make panle and corner embossing at a time.The fourth station is top flanging, the fifth station is bottom flanging.The bottom flanging: the can will be sent to the bottom flanging mold lying on the upper part of the machine by lifting tray to make it. The top flanging:the upper cylinder will press the can body to the position of top flanging mold to make it. Both the top and bottom can body flanging are each driven by four cylinders. The sixth station is automatic lid detecting and feeding and seaming.After the above six procedures, the can will be reversed up and down by reversing device,and then make top seaming,this process is the same as the bottom seaming process.Lastly,the finished can is fed by conveyor to automatic leak tester station.After accurate air source inspection, unqualified products are detected and pushed to a fixed area, and qualified products will come to the packaging workbench for the final packaging process.

Equipment composition of full-automatic production line of big square can

Single gang slitter

| Single gang slitter | |

| Maximum size of cutting material (L*W) | 1100*1100mm |

| Minimum size of cutting material (L*W) | 200*400mm |

| The fastest speed | 50 sheets/min |

| Power supply | 380v/50HZ |

| Total power | 3.5kw |

| Device Weight | 1800kg |

| Feed rack load capacity | 3T |

Full automatic welding machine

| Full automatic welding machine | |

| Welding frequency | 100-280Hz |

| Welding speed | 8m-15m/min |

| Production capacity | 25-35cans/min |

| Can body diameter | Φ220mm-Φ300mm |

| Can height | 220mm-500mm |

| Adapt to tinplate thickness | 0.2mm-0.4mm |

| Copper wire diameter | Φ1.5mm-Φ1.8mm |

| Weld seam amount | 0.6mm-1.0mm |

| Power supply | 380v 50Hz Three-phase power |

| Installed power | 20KW |

| Cooling water | >0.4MPa,12-20℃,40L/min |

| Air consumption | ≥200L/min>0.5Mpa |

| Device Weight | About 3000KG |

| Dimensions(L*W*H) | 2200mm*1520mm*1980mm |

Powder spraying machine

| Powder spraying machine | |

| Applicable can diameter | Φ52mm-Φ350mm |

| Transfer speed | 10-20m/min/20-60/min |

| Coating width | 6-14mm |

| Powder material | Polyester Epoxies |

| Installed power | 2.5KW |

| Air consumption | ≥300L/min>0.5Mpa |

| Input power | AC 220v,50HZ |

| Device Weight | 500KG |

| Dimensions(L*W*H) | 900*900*2200mm |

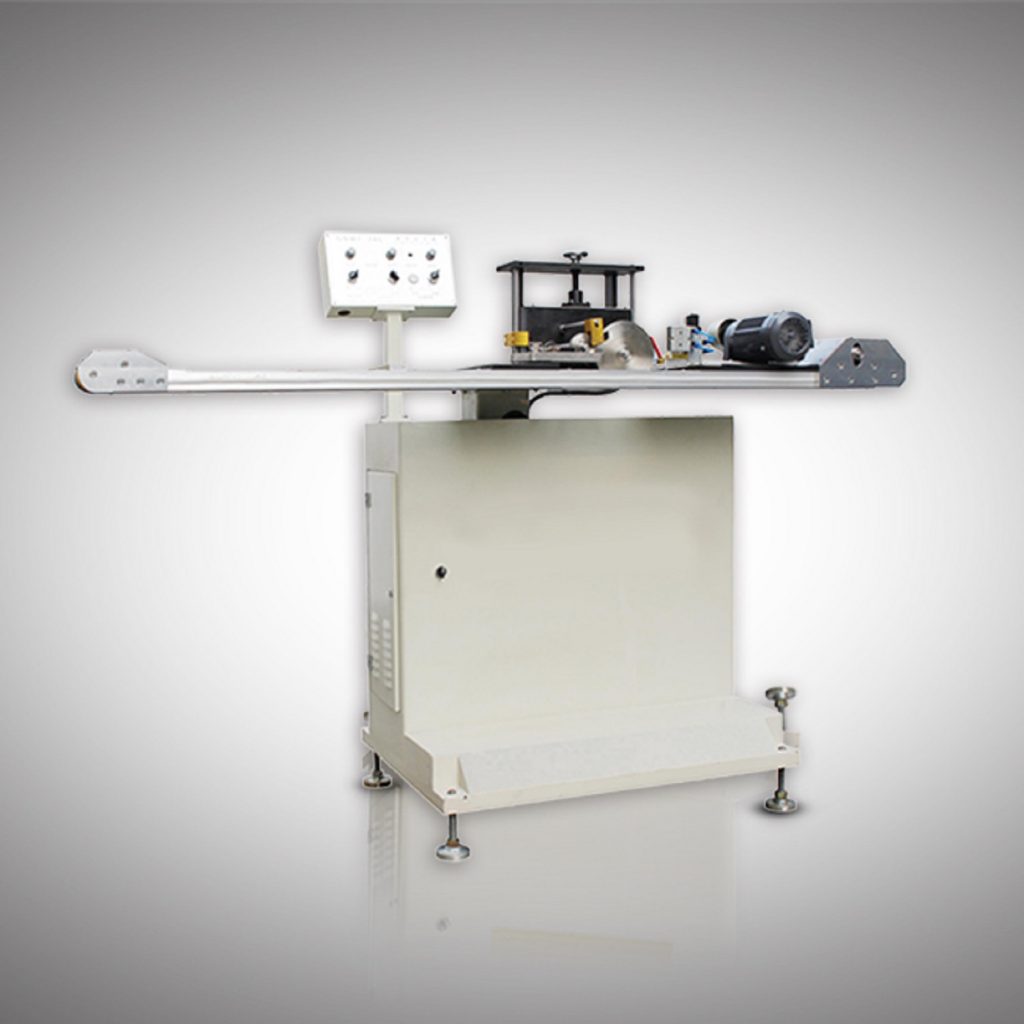

Full automatic coating machine

| Full automatic coating machine | |

| Applicable can diameter | Φ52Mmm-Φ350mm |

| Applicable can height | 50mm-600mm |

| Coating speed | 8-16m/min/25-50m/min |

| outside Coating width | 8-18mm |

| Compressed airm | 0.4MPA/cm² |

| Input power | ≥380v/50HZ |

| Dimensions(L*W*H) | 1800*600*1300mm |

| Device Weight | 500KG |

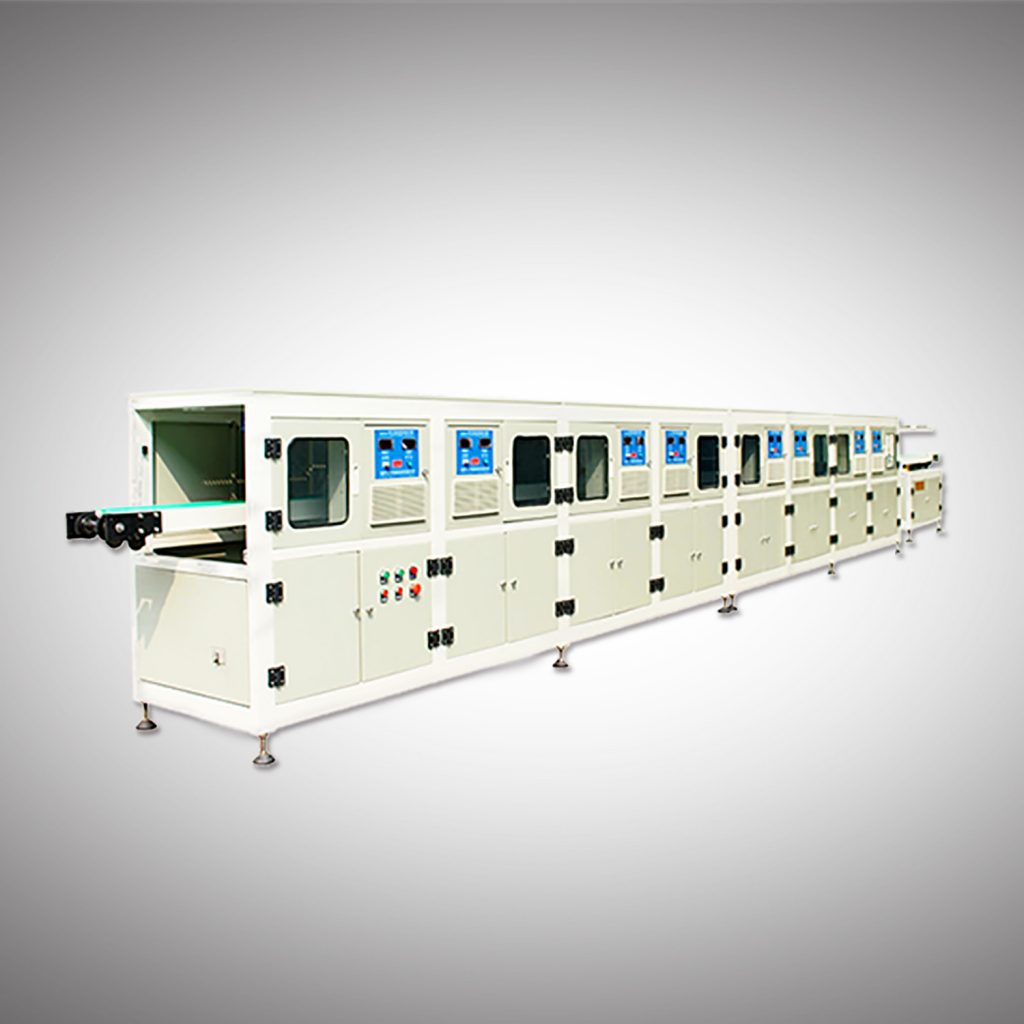

Electromagnetic drying machine

| Electromagnetic drying machine | |

| Burner power | 1-2KW |

| Burner heating speed | 4m-7m/min |

| Suitable small can diameter | Φ45mm-Φ176mm |

| Suitable big can diameter | Φ176mm-Φ350mm |

| Can height | 45mm-600mm |

| Cooling water | >0.4MPa,12-20℃,40L/min |

| Air consumption | ≥50L/min>0.5Mpa |

Full automatic can body combination machine

| Full automatic can body combination machine | |

| production capacity | 20-22 cpm |

| diagonal range | 300-320mm |

| can height range | 170-410mm |

| thickness | ≤0.4mm |

| total power | 42.94KW |

| pneumatic system pressure: | 0.3-0.5Mpa |

| body uprighting conveyor size | 3020*340*970mm |

| combination machine size | 3020*1420*3100mm |

| electric carbinet size | 700*400*1700mm |

| combination machine weight | 9T |

10-20L 8-Rollers Automatic square can seamer

| 10-20L 8-Rollers Automatic square can seamer | |

| production capacity | 20-22cpm |

| diagonal range | 300-320mm |

| can height range | 170-450mm |

| thickness | ≤0.4mm |

| total power | (3.75KW+lid feeding 0.2KW)*2 |

| pneumatic system pressure: | 0.3-0.5Mpa |

| the front section conveyor’s size | (2780*310*750mm)*2 |

| seaming machine size | (1350*1290*1980mm)*2 |

| electric carbinet size | (600*350*1400mm)*2 |

| seaming machine weight | 3T*2 |

Leak tester

| Leak tester | |

| Detected product volume range | 18L |

| Equipment air pressure | 4-6Bar |

| Check pressure | 10-15Kpa |

| Detection accuracy | 0.17mm |

| Detection speed | 20PCS/mins |

| Device Weight | 3800KG |

| Dimensions(L*W*H) | 4000mm*1200mm*2300mm |

| Input power | 380v/50HZ |

The layout of the production line

Tin can making artcraft