10-25L Conical Pail Production Line

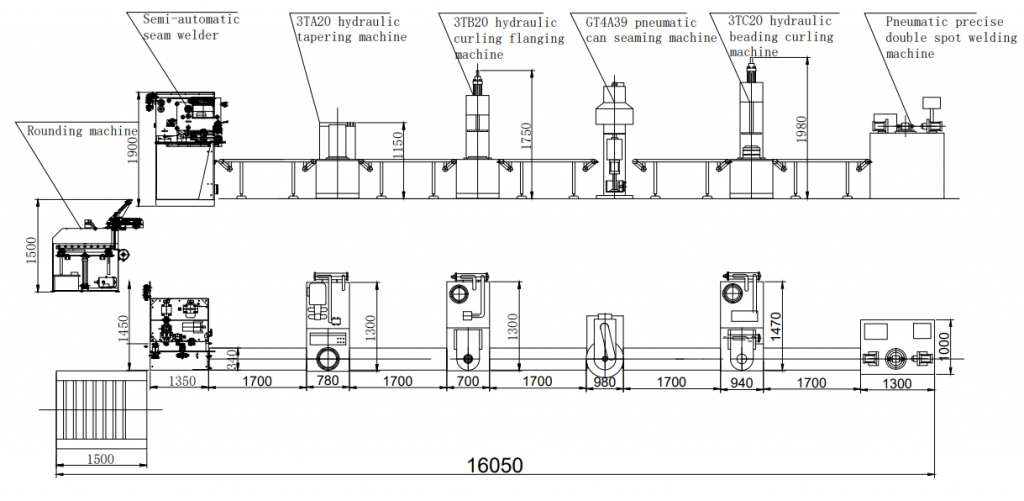

The production line is suitable for the automatic production of 10 liters to 25 liters’conical pail. total powder: approx.90KW,total floor space: 80㎡ .total length:approx.16 meters. total manpower: 9-10 people. Production capacity: 12-16cpm. Pail height range: 270-500mm. Pail diameter range:210-300mm

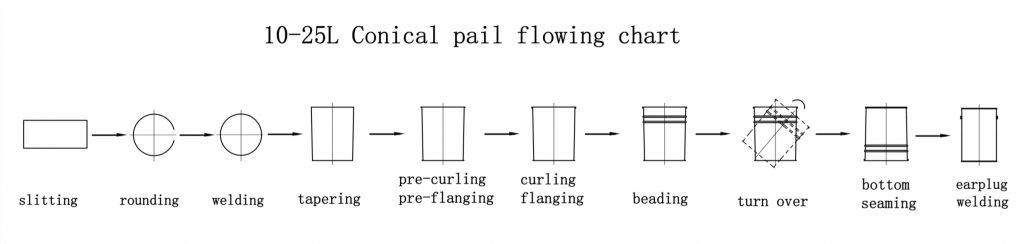

Technical flow: cutting the tin sheet to blank-rounding-welding-(manual coating)-conical expanding-flanging&pre-curling-curling&beading-bottom seaming-ear lug welding-manual handle assembly-packaging

What is a conical pail?

It is made of three pieces of metal sheet (mostly tinplate), the body, the bottom and the lid of the Cans. The cans is conical. The tank body has two ribs, Range of drums: capacity 20-25l, diameter 200-300mm, height 150-480mm.

Equipment composition of semi-automatic 10-25l conical round can production line

GT1B5B Can Slitting Machine

| Maximum thickness of cutting iron sheet | 0.18-0.5mm |

| Maximum width of cutting iron sheet | 1000-1250mm |

| Minimum width of cutting sheet | 40mm |

| Motor Power | 1.65KW |

| Dimensions(L*W*H) | (1470)1720×1000×1100mm |

| Device Weight | 1200-1500KG |

Automatic Rolling Machine

| Power supply | AC380V/50HZ |

| total power | 0.75KVA |

| thickness | 0.2-0.4mm |

| pneumatic system pressure | 40L/min Mpa |

| can height range | 120-300mm/120-400mm |

| diameter range | Φ52-105mm/Φ105-286mm |

| rounding speed | 40m/min |

| Dimensions(L*W*H) | 1500*700*1500mm |

Rear-feeding seam welder machine

| WeldingSpeed: | 6~12m/min(weldingpowerfrequency:50~240Hz) |

| Capacity: | 10~50cans/min |

| Diameter: | Φ52~180mm、Φ65~290mm |

| Height: | 70~270mm、70~420mm |

| Material: | 50#~100#Tinplateplate、steelbaseplate |

| Thickness: | 0.18~0.38mm |

| Overlap: | 0.4~1.2mm |

| Controlway: | PLC |

| Coolingwater: | ≤20℃ |

| Waterflow: | 20L/min |

| Waterpressure: | 5kg/cm² |

| Installationcapacity: | 16KVA |

| Dimensions(L*W*H) | 1350×1450×1900mm |

| Device Weight | 1200kg |

3TA20 Hydraulic Tapering Machine

| thickness | ≤0.5mm |

| diameter range | 210—300mm |

| can height range | 270—500mm |

| production capacity | 12-16cpm |

| Motor Power | 7.5KW |

| Device Weight | 1000KG |

| Dimensions(L*W*H) | 1300×780×1150mm |

3TB20 Hydraulic Pre-curling and Flanging Machine

| thickness | ≤0.5mm |

| diameter range | 210-300mm |

| can height range | 270-500mm |

| production capacity | 12-16cpm |

| Motor Power | 5.6KW |

| Device Weight | 860KG |

| Dimensions(L*W*H) | 1300×700×1750mm |

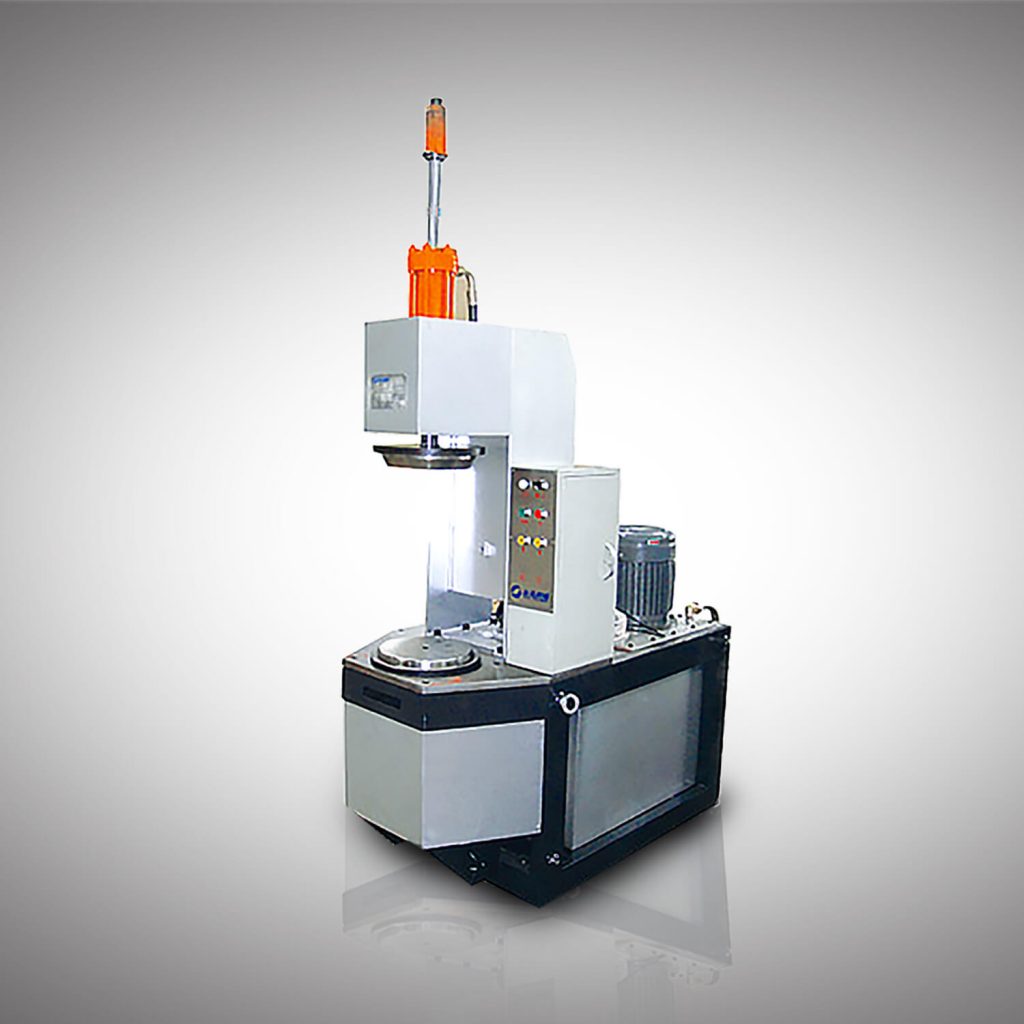

GT4A39 Pneumatic round can seamer

| thickness | ≤0.4mm |

| diameter range | 220-300mm |

| can height range | ≤400mm |

| production capacity | 15-20cpm |

| Motor Power | 2.2KW |

| Device Weight | 980KG |

| Dimensions(L*W*H) | 980*580*1900mm |

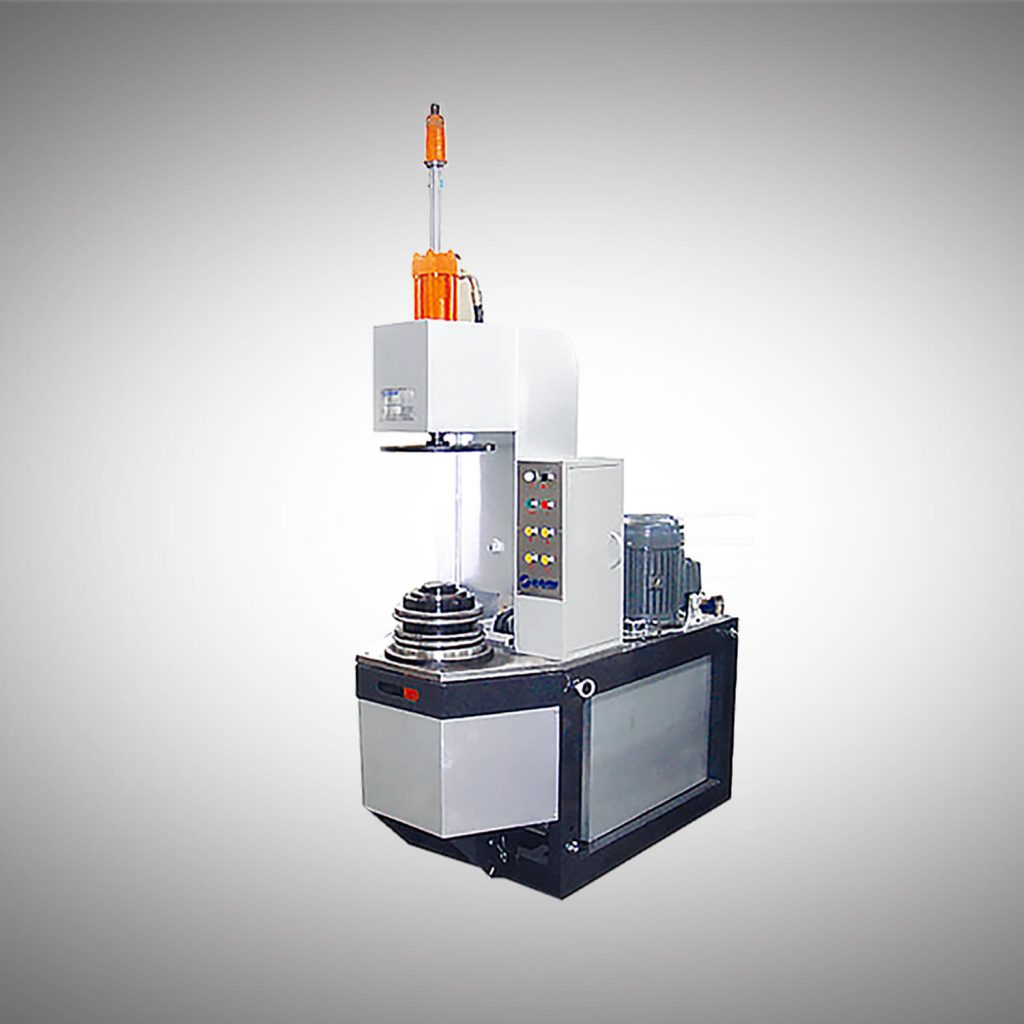

3TC20 Hydraulic Curling Beading Machine

| thickness | ≤0.5mm |

| diameter range | 210-300mm |

| can height range | 270-500mm |

| production capacity | 12-16cpm |

| Motor Power | 5.6KW |

| Device Weight | 1000KG |

| Dimensions(L*W*H) | 1470 × 940 × 1980mm |

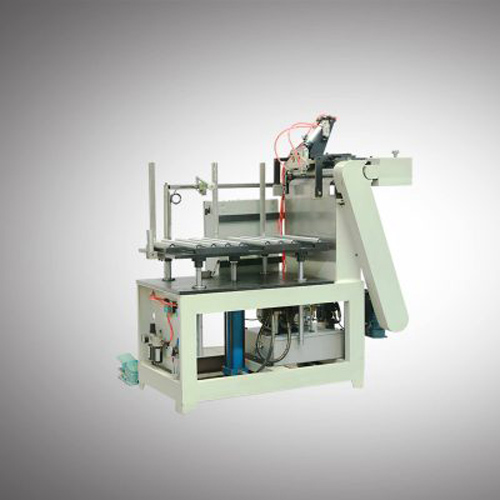

Auto feeding Double spot welder

| production capacity | 20-25cpm |

| electrode pressure | 1250N |

| diameter range | Φ220-300mm |

| load rate | 20% |

| primary current | 100A(Instantaneous) |

| air pressure | 0.5Mpa |

| air consumption | 200L/min |

| Device Weight | 380KG |

| Dimensions(L*W*H) | 1300*1000*1050mm |

| total power | 50KVA |

| Power supply | 380-440V |

The layout of the production line

Tin can making artcraft