conical pail bottom and cover fully auto machinery line

60epm D271mm Bottom Lid Line for Tin Pail Can making

Technical flow:Auto feeding device-Blank and form- Turn and conveyor-Stacking-Curling-Lining-Drying-Stacking-Output

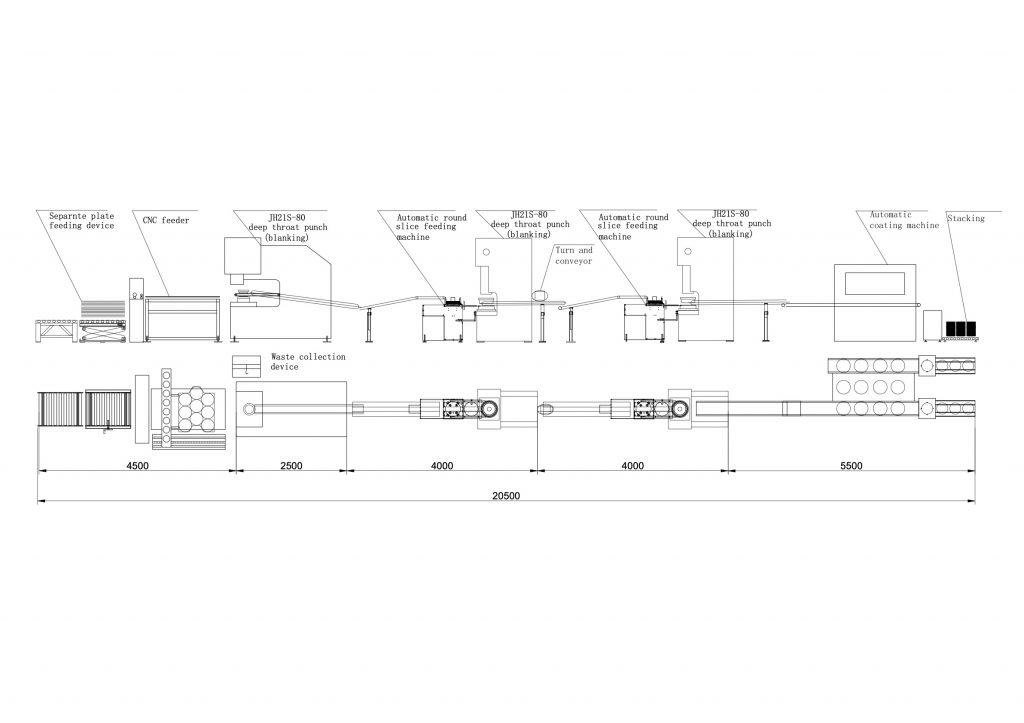

60epm Curled Lug Lid Line D282mm with EVA Gasket installed for Steel Pail Can Making

Technical flow:Auto feeding device-Blank and form- Stacking-2nd press for final forming-Turn and conveyor-3nd pressing for final forming-Glue strip-Output

60epm Lug Lid Line D282mm with EVA Gasket installed for Steel Pail Can Making

Technical flow:Auto feeding device-Blank and form- Stacking-2nd press for final forming-Turn and conveyor-Glue strip-Output

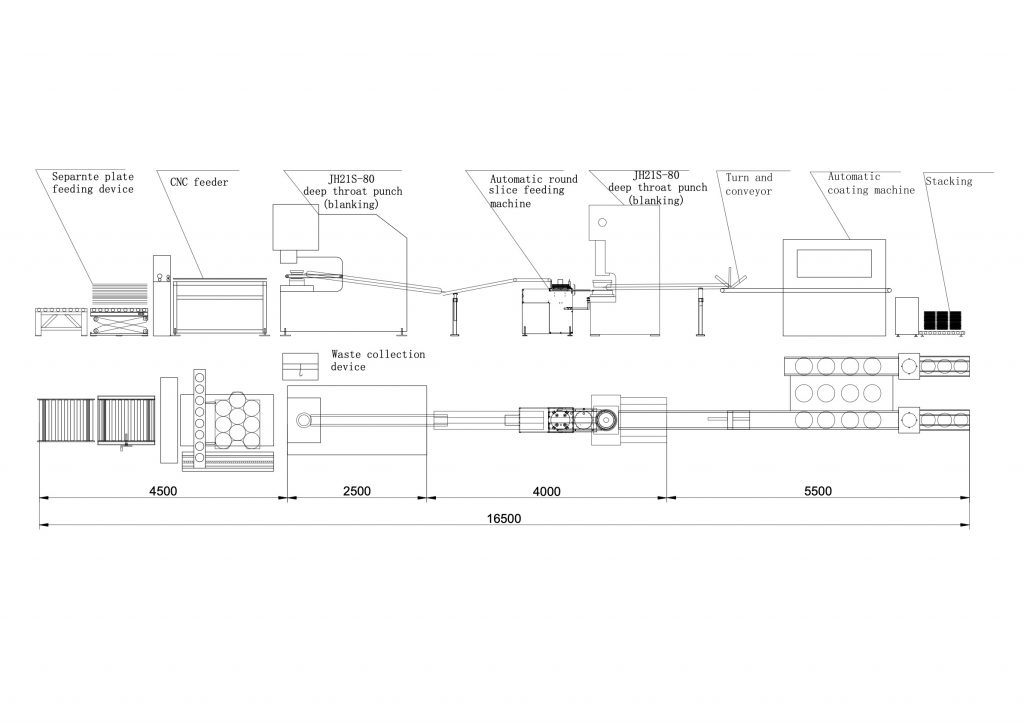

60epm D271mm Bottom Lid Line for Tin Pail Can making

The layout of the production line

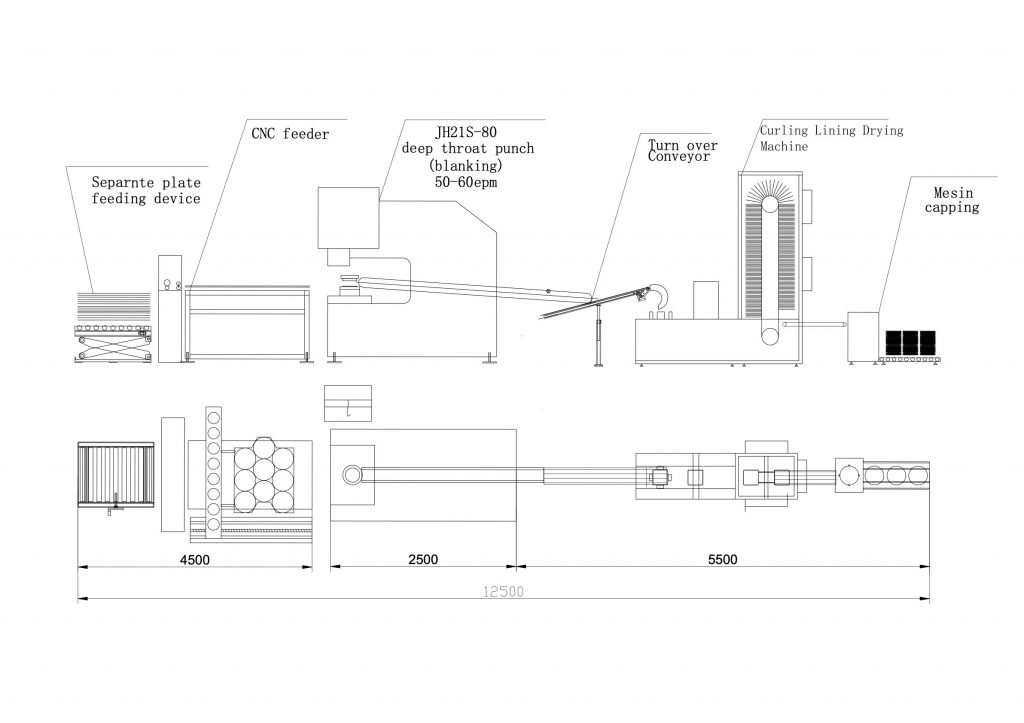

60epm Curled Lug Lid Line D282mm with EVA Gasket installed for Steel Pail Can Making

The layout of the production line

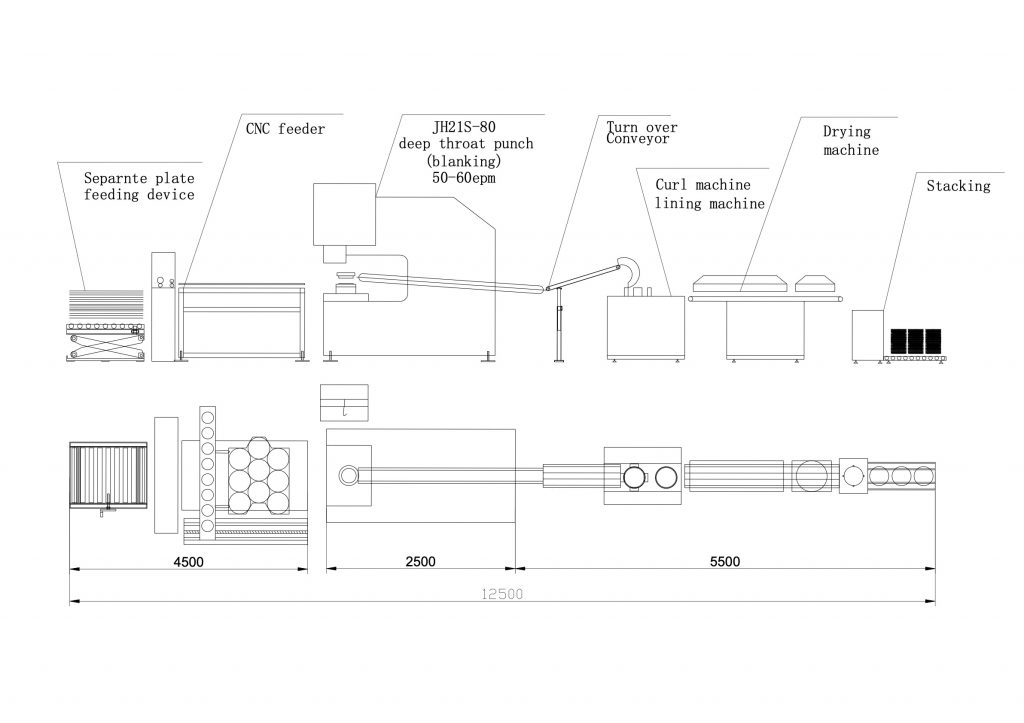

60epm Lug Lid Line D282mm with EVA Gasket installed for Steel Pail Can Making

The layout of the production line