With the rapid development of my country’s economy for many years, the per capita income and living standards of the people are increasing. Driven by the trend of consumption upgrading, personalized and high-end consumer packaging has become popular in the market, making aluminum bottles one of the best options for high-end packaging. With many advantages such as novel cans, recyclables, easy to carry, resealable, light weight, impact resistance, corrosion resistance, and good canning quality, aluminum bottles have been favored by consumers since their inception.

Many years ago, when Budweiser 355ml aluminum bottle beer was introduced to the market, it was sought after by consumers; Baijiu Erguotou used aluminum can packaging for the first time, which became a hot topic in the liquor industry; The huge beverage market segment is of great significance to the incremental space for metal packaging. In the past few years, some foreign high-end mineral water brands have adopted aluminum two-piece cans or even aluminum bottle packaging, and the appearance is quite amazing…. In recent years, there have been countless examples of aluminum bottle application innovation. Once new application trends and hot spots are discerned and captured, it is likely to inject development momentum into the metal packaging industry.

The characteristics and production process of IE aluminum bottle

The Impact Extrusion (IE) aluminum bottle technology was born in the United States about 20 years ago, and is almost the same age as the Draw and Wall Ironing (DWI) aluminum bottle technology from Japan, which produces bottle bodies. The process is similar to the aluminum two-piece can, and then it needs to go through multiple necking, flanging, thread making, and finally the aluminum bottle is formed. The difference between the two aluminum bottles

The production process of IE aluminum bottle involves the following seven steps.

Fried slices Lubricate the original aluminum discs according to the process requirements.

The first stamping and extrusion process produces straight blank cans in a concave-convex die.

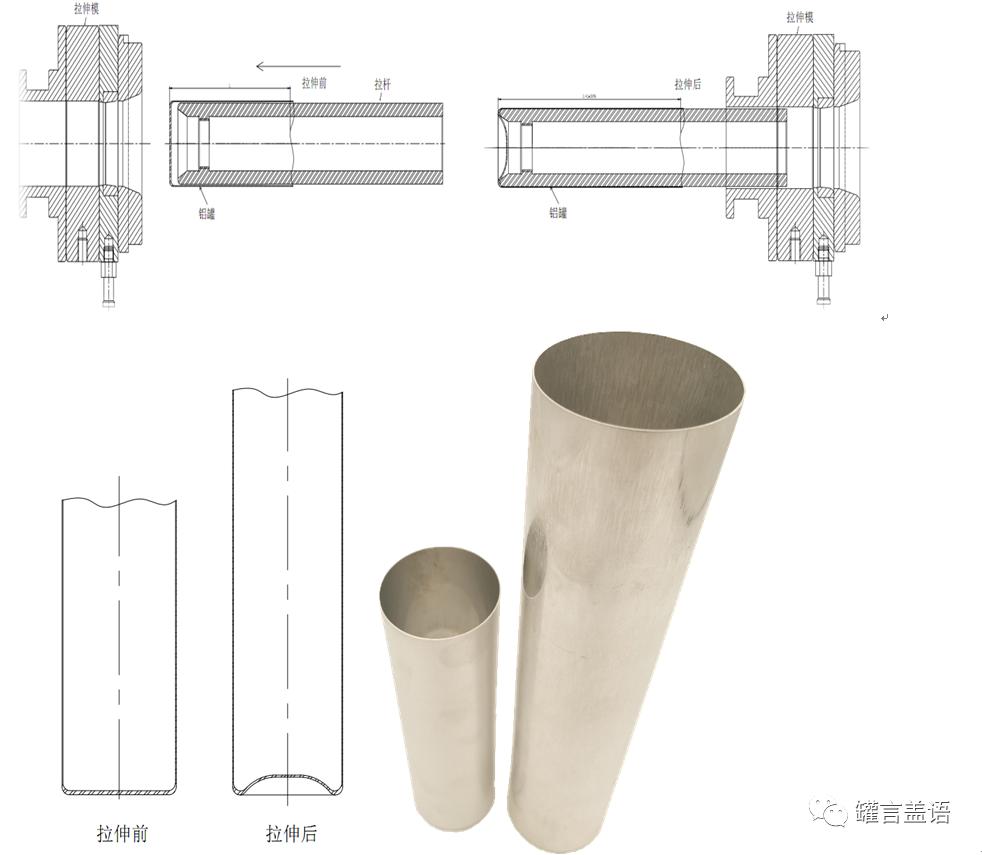

In the second stamping and extrusion process, according to the height requirements of the bottle and can, the straight cylinder can be impacted and squeezed for the second time to extend the height of the bottle body.

Trimming, polishing, drying After impact extrusion to form the required straight cans, “trimming + polishing” is performed, and then drying.

Internal Coating Spray the paint on the inside of the bottle.

Printing The bottle and can printing process includes: primer + baking; printing (9-color printing) + baking; glazing + baking.

Necking is the narrowing of the diameter to form the final product.

As shown in Figure 2, IE technology is especially suitable for making aluminum bottles with large diameter and long stroke (bottle height). (stretch) the purpose of the height of the aluminum bottle.

So far, the production technology and process of IE aluminum aerosol cans and aluminum bottles in China have been very mature. In particular, the production process quality inspection and implementation standards of IE aluminum bottles for wine are very strict, and must follow the “GB4806.10-2016 National Food Safety Standard for Food Contact Coatings and Coatings”, “GB4806.9-2016 National Food Safety Standard” Standard food contact metal materials and products” and “GB9685-2016 national food safety standard food contact materials and products with additives use standard” and other national standards. As one of the leading suppliers of IE aluminum aerosol cans and aluminum bottles in the market, our company’s product quality and safety, internal quality management system is mature and perfect, subject to strict and effective control, and product quality type inspection is carried out regularly every year (that is, the first Tripartite quality inspection), aims to identify product quality through authoritative inspection agencies, ensure that various quality indicators meet the requirements, and ensure product safety, reliability and environmental protection.

IE aluminum bottle manufacturing technology innovation and development trend

Fueled by industrialization, intelligence, and big data, the technological progress of the manufacturing industry is changing with each passing day. The manufacturing of IE aluminum bottles is no exception, and new technology applications are emerging one after another.

9-color high-definition printing The printing of traditional aluminum bottles is relatively simple, mostly solid printing, so the printing process is single, and the pattern lacks three-dimensional and realistic sense.

Through the use of laser engraving (DLE) plate making and 9-color letterpress printing technology in the production of aluminum bottles, the rich dots and layers can better present the realism of the product pattern. The printing effect is exquisite, natural and clear, and the reproduction of the physical pattern can be said to be lifelike and vivid.

Photochromic aluminum bottle The photochromic ink is printed on the aluminum bottle. After the ink is irradiated by sunlight or ultraviolet light, it can absorb the energy of sunlight or ultraviolet light and produce a change in molecular structure, which eventually leads to a change in the absorption wavelength and a color change. When the sun or ultraviolet energy is lost, the original molecular structure is restored and the original color is restored.

In addition to beer and beverage aluminum bottles, optically variable inks are also commonly used in aluminum aerosol cans for personal care products, among which sunscreen spray products are particularly typical. effect.

Thermochromic aluminum bottle Printing thermochromic ink on aluminum bottle, the ink changes color due to electron transfer at a specific temperature, resulting in a change in the molecular structure of organic matter. The basic temperature of thermochromic is -5~78℃.

Tactile Aluminium Bottles Tactile matte inks are formulated with high quality pigments and exhibit excellent hiding, lightfastness, adhesion and blocking resistance. The tactile aluminum bottle can give people a comfortable experience of “feeling thick, holding and warm”.

With the advancement of mold technology, embossed aluminum bottle can also be embossed on aluminum bottle. The body is processed with ever-changing embossed patterns. The embossed aluminum bottle can give the product the characteristics of “personalization and differentiation”, as well as anti-counterfeiting function.

Under the conditions of precise and fine mold processing technology, the whole body plastic deformation aluminum bottle can be made into various special-shaped aluminum bottles by changing the mold molding structure, adjusting the mold space, etc. .

The main battlefield and potential market of IE aluminum bottle

In recent years, with the continuous enrichment of IE aluminum bottle specifications and shapes, the application field is expanding.

Beer This is undoubtedly the main battlefield where IE aluminum bottles should be assembled. At present, glass bottles are the mainstream packaging in this market.

Light, oxygen and temperature are the three major factors that affect the quality of beer. Although the chemical properties of glass are stable and will not react with beer, it has poor light-blocking properties. The lighter the color of the bottle, the worse the light-blocking properties. “Photochemical action” occurs and “sunlight odor” occurs, thereby affecting the taste of beer. The aluminum bottle can effectively isolate the light by virtue of the general advantages of metal packaging; at the same time, the aluminum bottle beer freezes faster, making the beer taste more refreshing and more aromatic, plus the packaging is noble and elegant, and the material can be recycled, so the market A lot of IE aluminum bottles have emerged on the

Functional beverages The functional beverages packaged in aluminum cans are increasing year by year and are welcomed by the market and consumers. Representative cases include the new F6 Super Shot plant energy drink launched by BY-HEALTH in 2018, which changed the previous packaging method and used aluminum bottle packaging for the first time, eliminating the need for glass bottles to block light and inconvenience to carry to the product. troubles to come. The product design is flawless, from the theme concept to the ingredients to the aluminum can packaging. In particular, the design of the aluminum bottle is attentive and keeps up with the trend. The application of the layout color and pattern highlights the effect of the product. The new aluminum can packaged energy drink is pragmatic yet cool, and the appearance and strength complement each other.

Liquor In 2018, Beijing Erguotou Liquor Co., Ltd. took the lead in the industry to use aluminum bottles to package liquor, breaking through the solidification thinking of traditional ceramic and glass bottle packaging, realizing the innovation of liquor packaging, and bringing huge market response.

Another important aspect of using aluminum packaging is to promote environmental sustainability, for two reasons. On the one hand, the carbon footprint of glass bottles is much larger than that of aluminum bottles, which emit 20% less greenhouse gases than glass bottles during the production process. On the other hand, the recycling rate of aluminum bottles is very high, almost 100%, while glass bottles are less than 30%. Therefore, in terms of environmental sustainability, aluminum bottles have an absolute advantage over glass bottles.

Driven by the policy of “focusing on circular economy and environmental awareness”, as a more environmentally friendly alternative packaging, aluminum bottles are expected to gain huge development potential in the domestic liquor market with unlimited business opportunities.

In addition, the aluminum aerosol cans that are homologous to the IE aluminum bottle manufacturing technology are suitable as medicines, home care products (clothes wrinkle cleaning spray, clothing antibacterial spray, toilet spray, etc.), cosmetics, especially personal care products (spray Masks, spray band-aids, spray nourishing foam shower gel, vitamin antioxidant facial spray, etc.) and other products.

Epilogue

The manufacturing of aluminum bottles and application innovation can be said to complement each other. Manufacturing technology innovation is the basis of application innovation, and application innovation can bring pioneering thinking to manufacturing innovation. As a high-end packaging form that combines the advantages of PET/glass bottles and metal packaging, it is foreseeable that both IE aluminum bottles and DWI aluminum bottles will show their talents in the main battlefields such as beer in the future. The application prospects of the market are also worth looking forward to.